Fuel and Lubricant Solutions

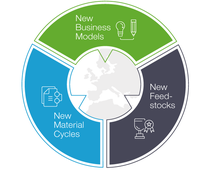

Circular Economy

New Feedstocks

Our biomass balanced product solutions already today help to reduce CO2 emissions and preserve fossil resources. The continously expanded product range, amongst others, includes OPPANOL® and GLISSOPAL® polyisobutenes, GLYSANTIN® coolants and BREOX® polyalkyleneglycols.

In the biomass balance procedure, fossil resources are replaced with renewable raw materials (biomethane and bionaphtha) in the very first step of the production process. The REDcert2 standard ensures the correct attribution of renewable resources in BASF’s value chain and to the respective products.

New Material Cycles

A key element of the specific implementation of new material cycles at BASF Fuel and Lubricant Solutions relates to product-specific recycling loops. Jointly with our project partners, we aim at creating a holistic overview of waste engine oil market. For this, we analyze material flows from finished lubricant to used oil distribution, collection, disposal and re-refined base oils production, including a discussion on technology, production infrastructure and regulatory framework. All with the clear target of keeping the material in use for as long as possible and by doing so contributing to the reduction of waste in this area.

New Business Models

BASF Fuel and Lubricant Solutions is strongly committed to driving market developments allowing that the use of biomass balanced, chemically recycled products and product-specific recycling loops can count towards recycling targets. In support of our customers, we create smart digital solutions and offer sustainability services.

Packaging

We improve the viability of our value chain by ensuring our products and packaging are designed to be safe for users and ecologically sound throughout their life cycle.