- Customized fuel additive formulations

- High-performance coolants for engines and electrical equipment

- Broad portfolio of high-performance lubricant components

- Solutions/flexibility to comply with regulations

- Improved durability/reduced maintenance

- Cost-effective solutions

Fuel and Lubricant Solutions

Marine

As a leading solution provider for fuels and lubricants, we are leveraging our chemical know-how and industry expertise to service our customers in the marine industry, delivering the exact solutions needed to face their challenges ahead.

Whether it comes to IMO 2020 (0.5% global sulphur cap for marine fuels) or the implications of VGP (restrictions on the use and discharge of lubricants) - BASF's Fuel and Lubricant Solutions help you stay on course!

Marine Regulations

The marine regulatory environment significantly impacts developments of the industry. This brings challenges but also opportunities. Having an innovative and reliable partner on board enables you to fully take advantage of those chances.

IMO 2020 Sulfur Cap

The International Maritime Organization (IMO) regulates shipping emissions globally, to reduce environmental pollution. Effective since Jan 2020, the allowed limit of sulfur in marine fuels was reduced from 3.5% to 0.5% globally, while in defined Emission Control Areas (ECA) the limit is 0.1%. This mandate is putting a severe challenge on refiners, who need to supply increasing volumes of compliant fuel blends, adapting to changing compositions. Bunker traders and ship operators must deal with price increases, a broad variety of fuel characteristics, stability and compatibility issues, and uncertain availability of the desired fuels.

At BASF's Fuel and Lubricant Solutions, we have a strong history in fuel additives. We leverage our experience to provide tailor-made additive formulations and help you overcome the various challenges that the sulfur cap is bringing (please scroll down further to Section 'Marine Fuel Additives'.

IMO NOx Regulation - TIER III

The control of greenhouse gases and pollutants, like NOx, is a major part of IMO regulatory activities. This becomes increasingly important, since control level Tier III reduces the limit of NOx emissions for larger ships significantly. IMO Tier III NOx controls have been applied in the North American ECA and US and Caribbean ECA since 2016 and will be introduced to North Sea ECA and Baltic Sea ECA in January 2021. Specified ships operating in these ECAs need to comply with Tier III limits. This usually affords the application of NOx control technologies.

Fuel in Water Technologies

Fuel in water technologies have been known to reduce NOx emissions in diesel engines for a long time. In the automotive sector the water represents only a minor share of the fuel mix. To comply with tier III limits in the marine industry, the amount of water needs to be significantly increased, up to 50% or more! The big ship engines can easily cope with this, if you use the right additives. At BASF we provide our customers with high-performance fuel additive packages to enable significantly reduced NOx emissions in a challenging fuel in water environment.

IMO 2030/2050

Besides the implementation of IMO 2020 S Cap, the agency is working to reduce GHG emissions from international shipping. The initial strategy envisages a reduction in total GHG emissions from international shipping and identifies these levels of ambition:

- Carbon intensity of the ship to decline through implementation of further phases of the energy efficiency design index (EEDI) for new ships to review with the aim to strengthen the energy efficiency design requirements for ships with the percentage improvement for each phase to be determined for each ship type, as appropriate;

- Carbon intensity of international shipping to decline to reduce CO2 emissions per transport work, as an average across international shipping, by at least 40% by 2030, pursuing efforts towards 70% by 2050, compared to 2008

- GHG emissions from international shipping to peak and decline as soon as possible and to reduce the total annual GHG emissions by at least 50% by 2050 compared to 2008 whilst pursuing efforts towards phasing them out as called for in the Vision as a point on a pathway of CO2 emissions reduction consistent with the Paris Agreement temperature goals.

Deeply anchored in its Corporate Strategy (Creating Chemistry for a Sustainable Future), BASF is fully committed to contribute to a sustainable development, and in consequence the reduction of GHG emissions.

Vessel General Permit (VGP)

The United States’ Vessel General Permit (VGP) program has brought very stringent regulations for the environmental friendliness of certain lubricants in the global shipping industry – such as those used for marine propulsion and steering systems. Environmentally Acceptable Lubricants (EALs) have become mandatory for lubricant applications where an oil-to-sea interface exists - such as stern tube, thrusters, propellers, stabilizers, and rudders. Beyond that, EALs are now also mandatory for wire rope and recommended for all other deck equipment (e.g., cranes, davits, winches, etc.).

The requirements for EAL‘s include:

- biodegradability

- non or minimal toxicity

- non-bio-accumulativeness

Lubricants labelled under OSPAR, Blue Angel, European Ecolabel and Swedish Standard are regarded as VGP-compliant. BASF offers great expertise in these relevant marine lubricant regulations and customers can benefit with our component solutions listed e.g. on LUSC, OSPAR etc. Furthermore, we can give guidance on regional chemical legislations like REACH, TSCA, K-REACH, etc.

Also see L. R. Rudnick; Lubricant Additives, 3rd Ed., Chapter 32, Eco Requirements for Lubricant Additives and Base Stocks (by Dr. M. Fies, Dr. T. Ruehle) for further details on EALs and bio lubricants in general.

Please contact us here for more information.

Marine Fuel Additives

At BASF's Fuel and Lubricant Solutions, we have a strong history in fuel additives. We leverage our experience to provide tailor-made additive formulations and help you overcome the challenges that the various regulations and changing environment are bringing.

Asphaltene Management Additives

Asphaltenes are polar macromolecules, which are usually kept in colloidal suspension in heavy fuel oils. Blending of these fractions with distillates, light cycle oils or marine gas oil may break up this suspension, leading to instable blends. These can be prone to aging and accelerated sedimentation or direct precipitation of the asphaltenes. Asphaltene management additives are specialized to mitigate the negative impacts on fuel stability caused by blending of incompatible fuels and fuel components. At BASF, we develop asphaltene stabilizers and tank cleaning dispersants. These prevent sedimentation caused by fuel aging (thermal or over time) and clean up deposits of asphaltenes.Furthermore, we offer compatibility agents which help to avoid asphaltene drop-out when blending of finished fuels occurs, e.g., in bunker tanks on-board or on-shore. As a result, less deposits form in tanks, pipes, filters and engines, and thus, safety and operating time will be increased.

Flow Improvers and Viscosity Modifiers

The broad variety of IMO compliant fuel oils also comes with significant differences in physical-chemical properties, such as viscosities and pour points. BASF offers a broad variety pour point depressants, flow improvers and viscosity modifiers, which help to bring these fuels in line and facilitate fuel handling.

Fuel in Water Packages

Fuel in water technologies have been known to reduce NOx emissions in diesel engines for a long time. In the automotive sector the water represents only a minor share of the fuel mix.

To comply with tier III limits in the marine industry, the amount of water needs to be significantly increased, up to a share of water that represents the majority of the mix!

The big ship engines can easily cope with this, if you have the right additives in place. We provide our customers with high performance fuel additive formulations to enable significantly reduced NOx emissions in a challenging fuel in water environment.

Fuel Additive Formulation Expertise by BASF

As your leading solution provider, at BASF, we will jointly work with you on your individual challenge at hand - and provide you with a tailored solution. To achieve this, we are leveraging our established technical experts and strong network of technical and R&D centers around the globe.

We have access to a variety of state-of-the-art test methods, as for example:

- Total Sediment Testing TSE, TSP and TSA according to DIN ISO 10307

- Quantitative and preparative SARA analysis (Saturates, Aromatics, Resins, Asphaltenes)

- Advanced tools like high-throughput robots

- Advanced statistical evaluations and predictive modelling

Marine Lubricants

As a leading components supplier to the lubricant industry, BASF Fuel and Lubricant Solutions can offer customers a broad range of sustainable high-performance components which help our customers formulate the top-class products needed and deliver sustainable solutions in the most challenging fields of application - for example, marine lubricants.

Engine Oils

Durability and efficiency are key parameters when it comes to marine operations, especially around the engine. BASF offers several solutions to enable e.g. MCLs (Marine Cylinder Lubricants), TPEOs (Trunk Piston Engine Oils) and SO (System Oils) meeting increasing performance demands. Changing landscapes due to IMO 2020 S Cap, but also further emission & efficiency targets like NOx and GHG (Green House Gas) emission reductions (IMO 2030, IMO 2050) are of focus for us.

Durability: Over time and during operation deposits are formed inside of any maritime engine. These deposits are based on organic and inorganic products, as for example, Ca-sulfate and Ca-carbonates. Those Ca-deposites eventually shape into needle-like deposits that may limit engine efficiency, increase oil consumption and causes corrosion. BASF's Fuel and Lubricant Solutions offers optimized performance components which address these challenges and help to remove and prevent the build-up of both organic and inorganic deposits.

Efficiency: Just as more severe efficiency targets have been implemented in the automotive sector, regulations on efficiency and emission control have become increasingly important for the marine sector. Related to upcoming challenges on IMO 2030 & 2050 BASF has expertise and component solutions to solve these tasks of tomorrow and guide the marine industry into clear waters.

Spotlights

While addition of our IRGANOX® L antioxidants to a marine engine oil formulation provide protection against organic deposits and enables long-life operations, our specialized SYNATIVE® ES ester take it one step further. These esters can be used as cleanliness agents to address the issue of both organic and inorganic deposits. To achieve best results BASF recommends the combined usage of Irganox® additives and Synative® base stocks for optimized marine engine oil lubricants.

Beside these spotlights, BASF offers comprehensive range of solutions for your lubrication needs (please scroll down further to Section 'Applications & Solutions'.

Auxiliary Equipment

Lubrication of the engine is not the only aspect to consider when it comes to durability, efficiency and cost savings. Versatile ship operations require specialized lubricants to guarantee smooth operations. Therefore, BASF offers great knowledge and component solutions in applications like:

- Hydraulic fluids

- Gear oils for the main propulsion, centrifuges, deck machinery and elevators

- Stern tube oils, thrusters, stabilizers, rudder lubricants

- Compressors (screw and reciprocating air compressors, vane compressors)

- Air and refrigeration compressor lubrication

- Turbine lubricants

With a broad range of innovative components being listed on the LuSC (Lubricant Substance Classification), BASF's Fuel and Lubricant Solutions enables the formulation of sustainable lubricants for marine auxiliary equipment.

You can find the comprehensive list of BASF's LUSC listed products for download here.

Spotlights

BASF offers a wide range of synthetic base oils like esters (SYNATIVE® ES) manufactured from sustainable and petrochemical raw materials, as well as a wide range of polyalkylene glycols (BREOX®, PLURASAFE® and PLURACOL®), including linear and branched polymers of alkylene oxide and specialized products to enable extra performance benefits and meeting Eco requirements.

Next to our Base Stocks solutions, BASF offers a broad portfolio of ashless (metal-free) additives and additive packages for the formulation of high-quality solutions in a wide range of applications. The portfolio includes antioxidants (IRGANOX®), friction modifiers / extreme pressure & anti-wear additives (IRAGLUBE®), corrosion inhibitors (IRGACOR®), metal deactivators (IRGAMET®), rheology modifiers (IRGAFLO®, GLISSOPAL®, OPPANOL®), emulsifiers (SYNATIVE® AC) and industrial additive packages (IRGAPAC®).

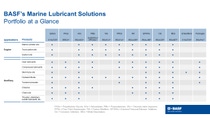

Applications and Solutions

Whether it comes to engine oils such as MCL (marine cylinder oils), TPEO (trunk piston engines oils) or SO (system oils) and auxiliaries such as, gears, compressor and hydraulics - BASF can offer a broad range of component solutions for marine lubricants.

Marine Coolants

Heavy duty motors in marine applications have high demands due to their long operating hours and high load rates. Marine coolants must protect against both corrosion and cavitation. Cavitation protection is especially important due to the increased vibrations associated with heavy duty motors. BASF has a broad portfolio of premium engine coolants with and without frost protection and special fluids for engine preservation that offer long-life protection to prevent damages and reduce downtimes. In addition, BASF has produced GLYSANTIN® engine coolants for more than 90 years, demonstrating broad expertise. The premium quality of engine coolants is confirmed by the official approvals of engine manufacturers.

Premium Engine Coolants with Frost Protection

Marine engines are normally cooled by solutions of corrosion inhibitors and water that do not exhibit protection against freezing. However, for operations in winter or in cold waters like in the North Sea or in arctic regions, protection against freezing is also required. In such cases, we recommend that engines are cooled with a coolant that is based on glycols and water, as it is typical for Automotive engines. GLYSANTIN® premium engine coolant from BASF provides comprehensive threefold protection against corrosion, overheating and frost. GLYSANTIN® avoids deposits and gives a high degree of corrosion protection to engine components such as radiators, cylinder blocks/heads, water pumps and heat exchangers.

GLYSANTIN® products are officially approved by engine manufacturers. In the following only the relevant approvals for marine and industrial application are listed. Industrial engines are used for example as generator sets for power supply on ships and vessels.

To see the full approval range for all application types, please go to www.glysantin.com

GLYSANTIN® coolant concentrates with frost protection are based on MEG (ethylene glycol) to ensure frost protection at temperatures below the freezing point of water, depending on use concentration.

Glysantin® G48®

Glysantin® G48® contains a corrosion inhibitor package based on salts of organic acids and silicates also known as Hybrid Coolant. It is usually available in blue-green color. Glysantin® G48® is free of nitrites, amines and phosphates.

Glysantin® G30®

Glysantin® G30® employs organic acid technology (OAT). Glysantin® G30® is free of nitrites, amines, phosphates, borates and silicates. It is usually available in pink color.

Glysantin® G40®

Glysantin® G40® employs organic acid technology and silicates (Si-OAT) which improve aluminum protection. Glysantin® G40® is free of nitrites, amines, phosphates and borates. It is usually available in pink color.

Glysantin® G64®

Glysantin® G64® employs organic acid technology with phosphates and silicates (PSi-OAT) improving flux compatibility. Glysantin® G64® is free of nitrites, amines and borates. It is usually available in green color.

Premium Engine Coolants without Frost Protection

BASF premium inhibitor concentrates are produced for application in marine and industrial engines in cases in which frost protection is not required and needed. Inhibitor concentrates for cooling water of combustion engines protect your engines against corrosion and cavitation. Due to the high amount of water, ready-mixed solutions exhibit excellent heat transfer properties to avoid overheating of an engine.

Glysacorr® G93®

Glysacorr® G93® is an inhibitor concentrate which is added to the cooling water of internal combustion engines to prolong the working life of the engine parts . Glysacorr® G93® is phosphate-, nitrite- and amine-free and is available in green, fluorescent color. Glysacorr® G93® affords excellent protection against cavitation and corrosion to all metals and alloys that are used in cooling systems, such as aluminum, ferrous and yellow metals.

Glysacorr® G93® is approved by the following engine manufacturers:

- German Military / Navy

- MAN Energy Solutions

- MTU

Special Coolant for Fuel Cells

Fuel cells have special requirements when it comes to cooling. The low electrical conductivity is of especially high importance to ensure safe operation of the fuel cell power unit. BASF developed GLYSANTIN® FC G20 to meet the requirements of fuel cell cooling systems.

GLYSANTIN® FC G20

Due to the selected non-ionic inhibitors used in GLYSANTIN® FC G 20, this product exhibits a very low long-term stable electrical conductivity. This ensures safe operation of the fuel cell power unit. GLYSANTIN® FC G20 is a corrosion inhibited ready-to-use coolant based on ethylene glycol, that offers a safe freeze protection down to -36°C and good heat dissipation. Metals, which are currently employed in the construction of PEMFC1 cooling systems are well protected against corrosion.

1 Proton Exchange Membrane = Polymer Electrolyte Membrane Fuel Cell

Special Products for Engine Preservation

BASF premium fluids for engine preservation provide high performance in engine tests and running-in of new engines which afterwards will be in transit or in storage for longer periods. The concentrates provide outstanding corrosion inhibition properties for all the metals and alloys used in engine construction.

Glysacorr® P88

Glysacorr® P88 is especially suitable as an engine break-in fluid for the break-in test of new engines and their subsequent storage (not suitable as long life coolant). It provides outstanding corrosion inhibition properties for all the metals and alloys used in engine construction. If it is diluted with water in a 1:1 mixture, Glysacorr® P88 provides frost protection down to -27°C.

Marine Lab Insights by BASF

One of three harbors at BASF's Verbund site in Ludwigshafen, Germany.

Advanced SITA Foam Testing

Advanced SITA Foam Testing

ASTM D 665 Rust Prevention Test

ASTM D 665 Rust Prevention Test

High-Throughput Facility, BASF SE, Ludwigshafen, Germany.

High-Throughput Robot

High-Troughput Robot