Fuel and Lubricant Solutions

Highly Reactive Polyisobutene (HR-PIB)

GLISSOPAL®

Find out more!

Discover our Customer Portal

Production Sites

With production sites strategically positioned in Ludwigshafen/Germany, Antwerp/Belgium, Nanjing/China and Kuantan/Malaysia, we leverage our strong supply and logistic position to cater to customers’ needs in our worldwide markets. Our unique global sales and distribution network in combination with our production footprint enable us to reliably supply our customers with high and consistent product quality and provide delivery security.

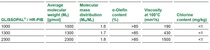

Product Grades

Polyisobutenes for the Lubricant Industry