Automotive & Transportation

5 ways material science is driving autonomous vehicle safety and design

As the race to fully autonomous vehicles continues, the technology that enables this revolution poses the biggest challenges - as well as the biggest opportunities - the automotive industry has ever seen.

While the industry is on the cusp of full autonomy, the technology powering this possibility has been on roadways for years. Vehicles today are equipped with safety-enhancing and driver assistance features such as blind spot monitoring, lane departure warning systems and parking assistance, all of which drive the industry closer to adoption, and acceptance, of fully autonomous vehicles.

As this technology evolves, the leading chemistry supplier to the automotive industry is looking at the challenge from a different angle - the power of materials. BASF is considering what solutions will complement and enable the intricate technology on the market and in development by proactively answering the following questions:

- Sensors and cameras are key components to how well a self-driving car performs on the road. What is the best way to house and protect these systems from environmental elements?

- Vehicle visibility is an increasingly important part of exterior design strategy. Is it possible to make a car's coating more reflective and detectable?

- Once the driver is no longer responsible for actively controlling the vehicle, how will materials make the passenger experience quieter, more comfortable and enjoyable?

- As the amount of technology needed to create a more personalized interior increases, is a lighter weight, more efficient vehicle still achievable?

- Autonomous vehicles are also likely to be electric. Do today's batteries have enough power to ensure longevity and quick charge capabilities?

"Algorithms and sensors are driving autonomous technology and our materials enable those advancements. We help cars 'see' through sensor protection and 'be seen' with advanced pigmentation and coating innovations," said Johannes Sprafke, automotive innovation manager at BASF. "The vehicle interior is also being re-imagined offering an opportunity to provide solutions that result in a quieter, more comfortable ride."

Here are five ways materials contribute to autonomous vehicle safety and design:

Protect autonomous vehicle sensors that allow the vehicle to 'see'

If sensors are the eyes of an autonomous vehicle, plastic encasements are its safety goggles.

The safety of a self-driving car depends on the accuracy of its sensors and cameras. Environmental influences such as heat, high humidity and road salts can deteriorate the plastic sensor housing and camera cases. Once these materials break down, the resolution and sensor readings are affected, which can compromise vehicle performance.

BASF offers a portfolio of materials that protect the integrity of these sensitive components. Its short- and long-range radar compatible plastics have high dimensional stability and are hydrolysis-resistant, an essential element to protect against environmental influences. BASF tests the safety of these solutions by using its specialized equipment to measure radar transparency and absorption at high frequencies.

"BASF works alongside automakers to develop the materials necessary to bring autonomous vehicles to market," said Dalia Naamani-Goldman, market segment manager, transportation at BASF North America. "With an emphasis on safety, we create high performing materials that ensure critical components, such as sensors, are protected and can function properly to provide a secure ride at any level of vehicle automation."

'Be seen' with advanced pigments and coating innovations

Chemistry experts at BASF are exploring how to increase visibility of vehicle coatings, specifically for dark colors that currently pose a challenge for LiDAR systems.

The dark pigments in use today absorb the wavelengths associated with LiDAR and radar systems, resulting in an inaccurate read for the autonomous system. BASF is developing an alternative to the carbon black pigment that increases reflectivity and enables the creation of dark coatings that are detectable to LiDAR systems.

"We have the expertise to bring functional colors to market that don't sacrifice aesthetic appeal and limit consumer choice when it comes to their vehicle color," said Paul Czornij, head of design, BASF Coatings North America. "The trick is to ensure all vehicle colors are compatible with future technology, not just lighter options."

Create a comfortable, clean and quiet driverless vehicle interior experience

BASF predicts that most autonomous vehicles will materialize in one of two ways: privately-owned premium vehicles, functioning as an extension of one's living room or office, or ride-hailing vehicles owned by mobility services.

For luxury vehicles, automakers can elevate the overall sophistication of the vehicle with high quality materials. Exclusive to BASF, valure is a special coating technology automakers can apply to surfaces to increase durability and create a soft-to-touch texture. And as the vehicle becomes an extension of one's home, the air quality standards should be in sync. Low-VOC polyurethanes keep emissions low and ensure the highest air quality in the interior.

For ride-hailing vehicles, the cleanliness of the car will be a primary concern. Antimicrobial, anti-dust and easy-to-clean materials become a necessity to address the revolving door nature of the robo-taxi.

For both variations of self-driving vehicles, noise, vibration and harshness solutions will be important. Once the passengers are no longer in control of the vehicle, sounds from the engine or bumps along the road will be more noticeable. BASF offers strategic NVH solutions to mitigate interference, see below for more information.

Offset technology and personalization gains with lightweight solutions

The increased technology needed to power driverless vehicles adds weight to the vehicle. And because the driver no longer needs to drive, these vehicles will likely feature increasingly customized components to optimize the passenger experience, adding even more weight.

Lightweight materials can help offset the increased mass associated with the technological, personalized components without sacrificing performance.

In fact, Ford recently tapped BASF to help lightweight its Lincoln Continental 30-Way seat. The seat's lower cushion, seatback, headrest, upper-back, thigh and lumber support are adjustable to individual specifications for optimal comfort. BASF was able to reduce the weight of the seat pan by 20 percent, contributing to an 8 percent reduction in the entire seating system.

Developing a longer-lasting battery with quick charge capabilities

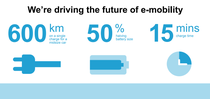

Most concepts for fully autonomous vehicles have an electric powertrain, increasing the need for smart battery materials and quick charging capabilities.

BASF's battery materials division has made significant investments in R&D to address current industry challenges such as range, size and weight of battery components and charge time. These advancements will be critical to powering self-driving vehicles.