Automotive & Transportation

Creating sustainable, lightweight automotive composites with spray transfer molding

Fresh from his presentation earlier this month at the Automotive Composites Conference & Expo, Dr. Elias Shakour, BASF Project Leader - Composites Technologies, shared insights on how sustainability is playing a role in the lightweight composites conversation for the automotive industry.

Specifically, Elias discusses spray transfer molding and the use of natural fibers in conjunction with polyurethane solutions.

What is Spray Transfer Molding (STM)?

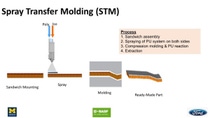

Spray Transfer Molding (STM) is a fast and efficient process to manufacture lightweight composite materials.

It is within 60-90 seconds where the fabric is impregnated outside the mold using a high-pressure spray process, then molded in a compression press. A blank of dry fiber is held by a programmable robot that has an optimized and controlled spray pattern. Once sprayed using a high-pressure nozzle head atomizing the spray PU, the robot will lay down the impregnated blank into the tool to be fully molded and cured. For this study, we used a state-of-the-art bamboo random fabric mat which was laid on top and bottom of honeycomb to make honeycomb sandwich parts. The process is designed to scale from initial ideation and experiments to actual automotive production components.

Why are you looking at a sustainable solution with BASF polyurethanes?

BASF is always looking for favorable sustainable ways and means for innovative automotive solutions and implementing new products in industry. Sustainable development means we are committed to protecting the environment without compromising performance. Sustainable PU Elastoflex® 28690 has a high percentage of sustainable bio-based content, low demold time, non-sag formulation, good open time to make large parts and is compatible with multiple natural reinforcement fibers such as bamboo, jute and hemp.

Why bamboo?

There are amazing attributes that naturally occurring bamboo fibers provide for the PU, as an effective replacement to glass and non-structural natural fibers because of its rather high mechanical performance. Bamboo has so many favorable structural advantages, such as being renewable, having an incredible growth rate, superior mechanical and flexural behavior, low density, being able to be extracted as long, continuous fibers as well as a LCA benefit. Bamboo-reinforced composites have high energy absorption that leads to be well suited for structural and semi-structural parts in the automotive industry.

Does the sustainable PU perform at the same level as standard PU?

Mechanical performance of sustainable PU was shown to be similar to the commercial PU in terms of flexural strength and flexural modulus. Using sustainable PU and bamboo for automotive composites offers light weighting advantages, up to 20-50 percent, helping automakers create fuel efficient vehicles with improved performance and strength. Sustainable, natural fiber-reinforced composites can compete with traditional materials and are well-suited for both interior and exterior applications.

What applications can this be used for in automotive?

These lightweight composites can be used for many applications in the automotive industry such as door interiors, arm rests, load floors, sun shades, hatchbacks and package shelves.

What are the next steps with this technology?

The next steps will be working with automotive Tier 1 and OEMs for applications for door interiors and load floors. To drive new innovations in automotive solutions technology, BASF opened a customer innovation center with a world-class, production scale development lab. Using STM, BASF can co-develop lightweight composites from load floors to more advanced structural applications.

How can OEMs and Tiers learn more about STM?

OEMs and Tiers interested in learning more about STM and natural, bamboo fiber composites should contact us.