Automotive & Transportation

Winning the race to mainstream EVs requires a better battery. BASF can help.

The US is planning to transition its automotive fleet to EVs, with an aggressive goal of having half of new vehicles be electric in 2030. The number of EVs sold in China are expected to increase between 2.4 million and 3.5 million in 2022. In Europe, strict emission targets are potentially pushing market share higher, with EVs expected to have a 12-15 percent market share by next year.

While strides have been made in the push toward electrification, widespread adoption will be largely dependent on advancements in battery technology. Along with an adequate charging infrastructure, emissions regulations and other factors, consumer adoption plays a pivotal key role in the future of eMobility. Consumers want an electric vehicle with long range and short charging time at a reasonable price.

BASF is a leading high-energy density cathode active materials supplier for lithium-ion batteries, the power source for EVs. Cathode active materials are key components that determine the efficiency, reliability, cost, durability and size of the battery. Vuk Milojkovic, CEO of BASF Toda America and Director of Battery Materials, NA, explains, “When you look at the chemistry of the cathode materials, it’s really the main lever you have to impact key properties of the battery. Those properties are what enable longer vehicle driving range and shorter charging times. They can also be customized to achieve the right performance and the right cost structure for each customer.” The chemistry BASF is developing helps advance the technology of lithium-ion batteries, which in turn will help overcome barriers to broader consumer EV adoption.

A virtual tool for exploring battery pack solutions

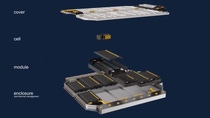

Cathode active materials are only one piece of the battery materials puzzle. To highlight all of its solutions that help manufacturers make battery packs better and stay ahead of eMobility trends, BASF created the Battery Pack Visualizer tool. Customers can explore different parts of the battery pack to determine which BASF solutions can best address their needs or inspire new innovations for eMobility.

BASF’s portfolio for the battery pack starts at its heart with cathode active materials for the battery cells, as well as binders for pure graphite and silicon-containing Li battery anodes. Moving to the module, BASF provides plastics solutions for the housing and the end plate. For metal housing covers and bottom trays, specified multi-metal pretreatment processes are available. Ending this journey at the battery pack enclosure, the portfolio is completed by polyurethane systems; thermoplastic polyurethanes and Polyamide-based (PA) particle foams. Damping pads made of the microcellulare polyurethane Cellasto installed on the battery pack enclosure can reduce vibrations between body and battery module, improving passenger comfort, battery lifetime and safety.

In the context of safety, thermal management is key - especially during fast charging processes, batteries heat up and, thus, need an active cooling. For this, BASF offers coolants with high heat transfer. In the intermediate layer between the battery module and coolant plate, a thermal interface material is needed to bridge this gap so that heat can be directed from the cell to the coolant. BASF offers polyurethane-based, thermally conductive adhesives that are easy to dispense onto the surface of the coolant plate.

Besides electric applications like orange high-voltage connectors and busbar holders, the battery also contains a lot of fluid valves and pipes that join the coolant channels. Whether customers need to meet the high demands of flame retardancy or hydrolysis resistance to protect the integrity of sensitive electronic applications, BASF offers a broad portfolio of engineering plastics and profound consultancy to find the ideal material match for all aspects.

BASF continues to work on innovative solutions that enable future battery technologies. For example, electric vehicles with bigger batteries may have longer ranges, but are also burdened with additional weight. The topside of a battery cover is typically made of steel or other plastic composites. BASF is benchmarking these existing materials and trying to make them lighter yet stronger by assessing new composite solutions for the battery cover.

“We’ve tapped the expertise of our colleagues across business units and regions to showcase, through the Battery Pack Visualizer, BASF’s broad portfolio and how our materials contribute to eMobility advancements,” said SweeJin Saw, Segment Marketing, E/E Modules & eMobility at BASF. “We understand what our customers need to meet growing industry demands now, while also developing new solutions to address the challenges our materials cannot meet today.”

Check out BASF’s solutions for the battery pack to learn more about how we’re creating an electric and sustainable future.